Dust Extractors For Small Workshops Things To Know Before You Get This

Table of ContentsRumored Buzz on Dust Extractors For Small WorkshopsSee This Report on Dust Extractors For Small WorkshopsDust Extractors For Small Workshops for DummiesOur Dust Extractors For Small Workshops Statements

The obstacles for shop dust collection systems rotate around crystalline silica dust, carbon monoxide, and heat, which are harmful combinations. These factors make conference air top quality requirements hard and also requiring. When choosing a dirt control system for a shop, the very first consideration is the capacity of the system to stand up to extreme as well as dangerous workplace problems.

Dirt collection systems for this type of operation need to be particularly designed to fit the type of finishing being applied. The purpose of the system is to manage and minimize overspray and also dust.

It would appear likely to increase air flow and activity, this kind of service might be inefficient and also waste energy. The style of the cubicle depends upon the pressure of the air entering the cell or cubicle. For many systems, it is vital to have a small vacuum cleaner in the booth to avoid feasible positive pressure.

Not known Facts About Dust Extractors For Small Workshops

An additional method is simply positioning the makeup air connection on the top of the cubicle. Regardless of the layout, it is essential for the cleansing of the air to have cross ventilation. Just like a cleanroom, air movement in a thermal spray cubicle can be either horizontal or downward, though the down style is best for dust collection systems.

The pharmaceutical sector is an extremely regulated sector with comprehensive as well as precise policies. Dust from pharmaceuticals is created mainly during the manufacturing and product packaging of items. Each action of generating a drug, that includes granulating, drying out, mixing, pushing, layer, and also grinding, produces huge amounts of dirt that require to be removed.

Intercepting and controlling this circulation is the feature of the dirt control system. When creating a dust control system for a pharmaceutical plant, the initial see this site factor to consider is mapping the ventilation system to visit homepage track the path of dust, fumes, existing airflow patterns, as well as possible transformative adjustments. Since many pharmaceutical dusts are flammable, the layout of the air flow system is extremely vital.

HEPA filters are typically located in pharmaceutical dirt control systems since they are one of the most effective as well as reliable. As with a shop system, they are installed as an additional protection to achieve absolutely no emissions. Recycling creates a good deal of dust as a natural result of diminishing things to their basic materials.

Facts About Dust Extractors For Small Workshops Revealed

Dust stems after materials are shredded, squashed, or have paint or lacquer eliminated. All reusing centers are required to abide by air quality requirements. As they function to satisfy quality criteria and control toxins, they have actually recognized that dirt control is a significant concern, resulting in the vast usage of dirt collection systems to mitigate and consist of the problem. dust extractors for small workshops.

When makers pick a dirt control system, they are suggested by producers concerning the kind of system that would best fit their demands given that buying as well as setting up Resources a dust control system is a significant financial investment. Particle issue can be found in a wide variety of forms, from silicon dirt to timber chips and also sawdust.

Dust Extractors For Small Workshops Can Be Fun For Everyone

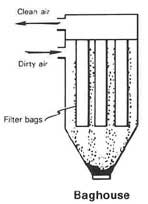

Textile filter bags in a cartridge system are one of the most effective technique for gathering dust. Cement Cement dust is produced during the movement as well as transport of the product. Dirt collection systems are covered to consist of the dirt as well as tidy the air. Clay Clay dust is created in the production of bricks.

Plastic Dust High-Density Polyethylene (HDPE) dust is generated in the manufacturing of plastic panels when they are shaped and also created on an edge trimmer, grinder, or miter saw. Paper Dirt Among the more common types of dirt is paper dirt, the negative effects of the manufacturing of numerous kinds of paper.

With the intro of dirt collection systems, employees are much safer and also a lot more secured. Sugar Sugar dust is the by-product of the production of sweet.

Rice Dirt Rice dust has extremely fine and minute fragments that accumulate during the manufacturing of rice-based items. A dirt collection system is needed for the protection as well as safety and security of workers.